Corroline Plus

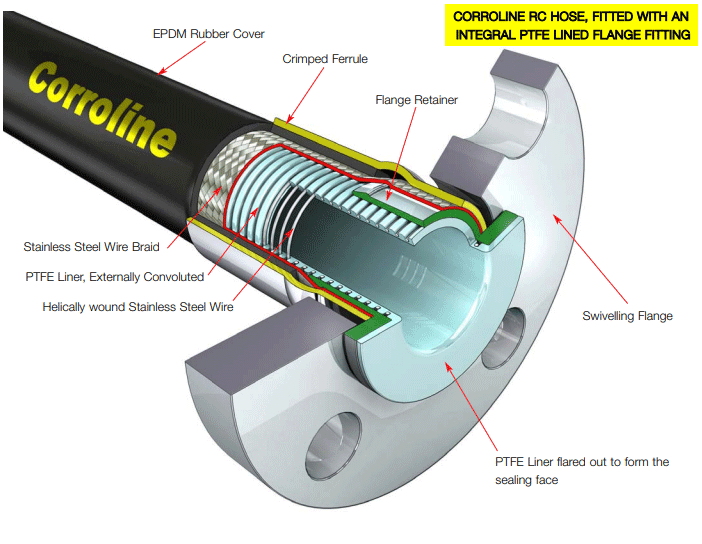

INTRODUCTION INTRODUCTIONCorroline hose was designed and developed to provide customers with a universal chemical hose product which combined all the requirements they had requested for chemical plant applications, particularly the need for improved flexibility. Corroline hose not only supersedes but also improves upon the wide variety of alternative Chemical Hose products currently available. CONSTRUCTION Corroline is built around a patented PTFE hose liner design, which has a slightly rippled smooth bore inside, but convoluted outside to generate excellent flexibility combined with “hoop strength”. A stainless helical wire is wound in to the external convolutions, which adds to the kink resistance, crush resistance and the resistance of the hose to both pressure and vacuum. This reinforced PTFE Liner construction is strong enough to withstand full vacuum and kinking without the need for either internal convolutions or the need to bond the liner to an outer cover, making it an ideal hose liner design, and a significant improvement upon standard products currently available. The PTFE liner is then further reinforced with an outer braid, either a Stainless Steel wire braid (SS Grade) or a Polypropylene braid (PB Grade) to provide two braided hose grades. The most popular grade (RC Grade) includes an outer cover of abrasion resistant, black antistatic EPDM rubber which is extruded on to a SS braided liner, with a super-smooth surface finish to aid external cleaning. A yellow, “CORROLINE” stripe is printed on to the cover. Other texts and colored stripes are also available to special order. Pressure and Temperature LimitationsMaximum Working Pressures – Burst Pressures – Vacuum LimitationsUsable at vacuum to -0.9bar up to 150˚C/302˚F. FlexibilityMuch less force to bend than any other smooth bore PTFE lined hose product. Kink ResistanceMuch more resistant to kinking than any other smooth bore PTFE lined hose product, and much more kink resistant than the previous Corroline product. Fire resistanceCorroline+ hose is Fireproof to BS5173 Section 103.13 Parts 6.2 and 6.3, and Corroline+ hose assemblies can be upgraded to Fireproof by applying DBK 300 at each end. All assemblies comply with the flammability requirement as set out in EN 16643. ‘Rolling U’ Flex Life TestMore than 100 × the flex life to failure compared with all other types of smooth bore PTFE, FEP and PFA lined rubber covered hose products. Flow ratesMore than 2 times the flow rates for convoluted bore hose designs. Consult Aflex Hose for specific flow rate information. Gas permeabilityReduced gas permeability compared with other PTFE lined hose designs, due to the heavy compression applied to the PTFE during processing, which reduces porosity. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||