- Corrogated Metal Hose:

- Fast-Flow Stock Assemblies

- Pump Connectors / Vibration Eliminators

- Annuflex

- Masterflex

- Pressureflex HP

- Pressuremax HP

- Chemking

- Cholorsafe

- Cryogenic Hose Assemblies

- Formaflex

- Extraflex

- Hydraflex

- Bronzeflex

- Stripwound Metal Hose

- Roughbore

- Interflex

- T-Rex

- Smoothbore

- Ultraflex

- T-Rex SB

- Floppyguard – Hose Protection

- Roughbore

There are a variety of demanding applications where using metal hose can be critical in determining success. These include applications requiring corrosion resistance, extreme high and low temperature capabilities or high durability. Environmental characteristics that also demand the use of metal hose are dynamic flexing, expansion and contractions and high vacuum. There are two main types of metal hose Corrugated Metal Hose and Stripwound Metal Hose, use the links to explore more about how each is used and see our broad range of offerings.

Full Range of Metal Hose Offerings:

McGill Hose stocks 3/16″ through 8″ diameter metal hose in a variety of alloys, pressure ratings and flexibility options. We stock full reels of product making long length assemblies a common problem solver we’re able to supply.

|

|

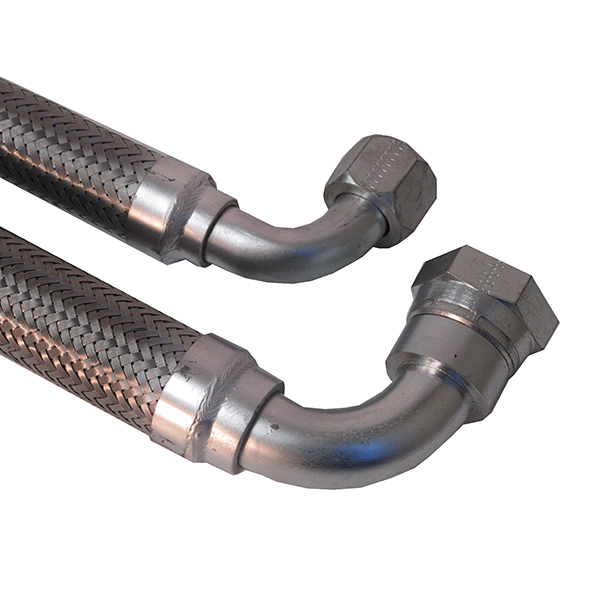

Fast-Flow in Stock Assemblies:

Metal hose assemblies are the cornerstone of our Fast Flow program. Standard-sized threaded and flanged assemblies are available for same-day delivery. See our price list, size and material options by visiting our Fast-Flow Hose Assemblies page.

Custom Assemblies are our specialty. We compliment our metal hose fabrication with an in-house machine shop for special fittings and our tube bending facility for special shapes for hard to reach connections. We can quickly and accurately work from concept, to design, to final ready to use assembly.

Experience and Safety:

McGill Hose has been a leader in fabricating flexible metal hose assemblies since 1962. Our hoses are designed and fabricated to the NAHAD Hose Safety Institute, ensuring consistent quality and safe assemblies. Furthermore, our welders are certified to ASME IX B31.1, a voluntary standard that promotes safety and reliability in pressure piping applications. (Please visit www.asme.org for more information on this standard.)